3D Printing in a FAB Shop

Russell AlexanderJan 3, 2020, 4:51:23 PM

A quick post about a 3D printing idea for modern fab shop. Ways to use this amazing and inexpensive technology in more traditional trades.

And a quick shot at one of these blogs, just for the hell of it.

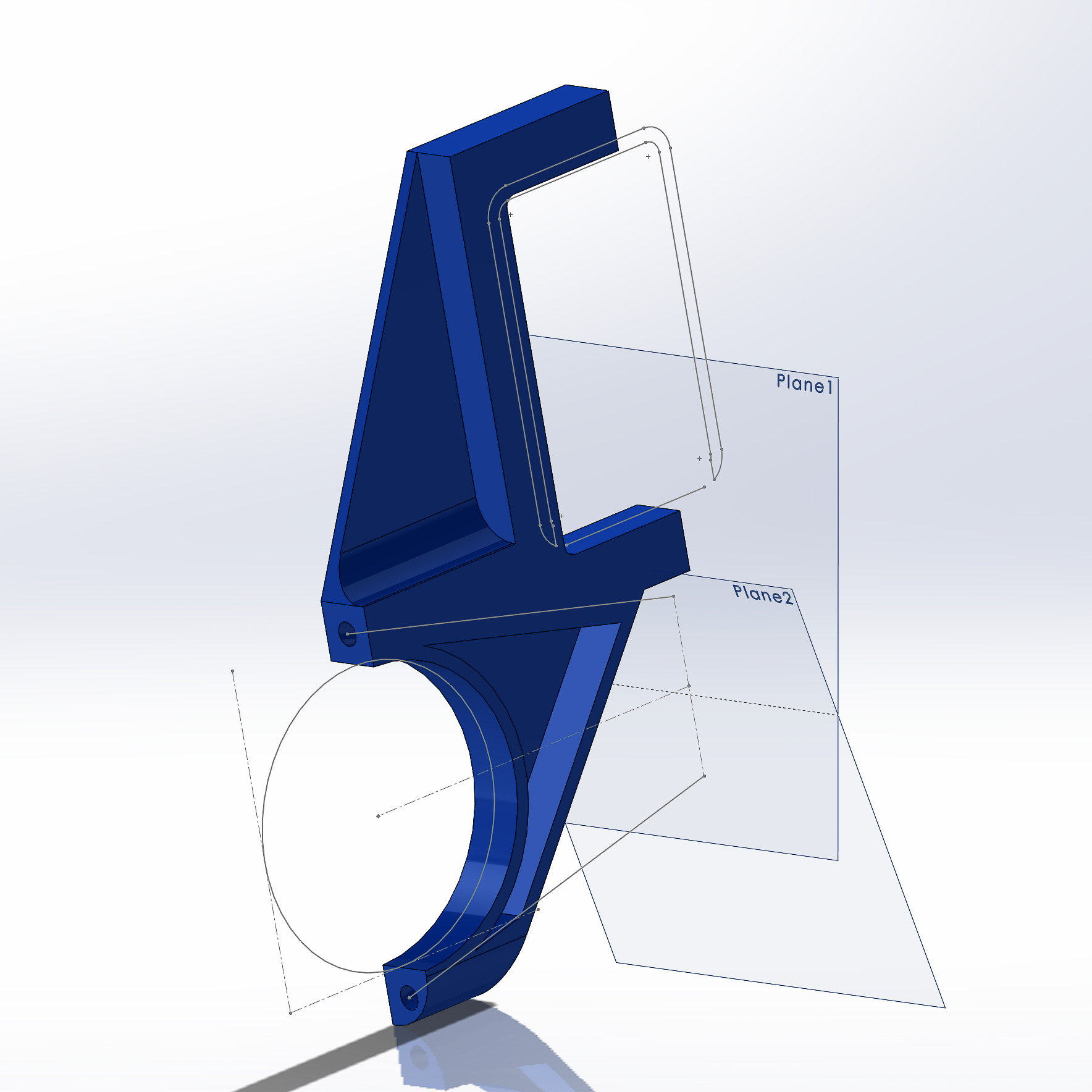

Designing the Locating Jig

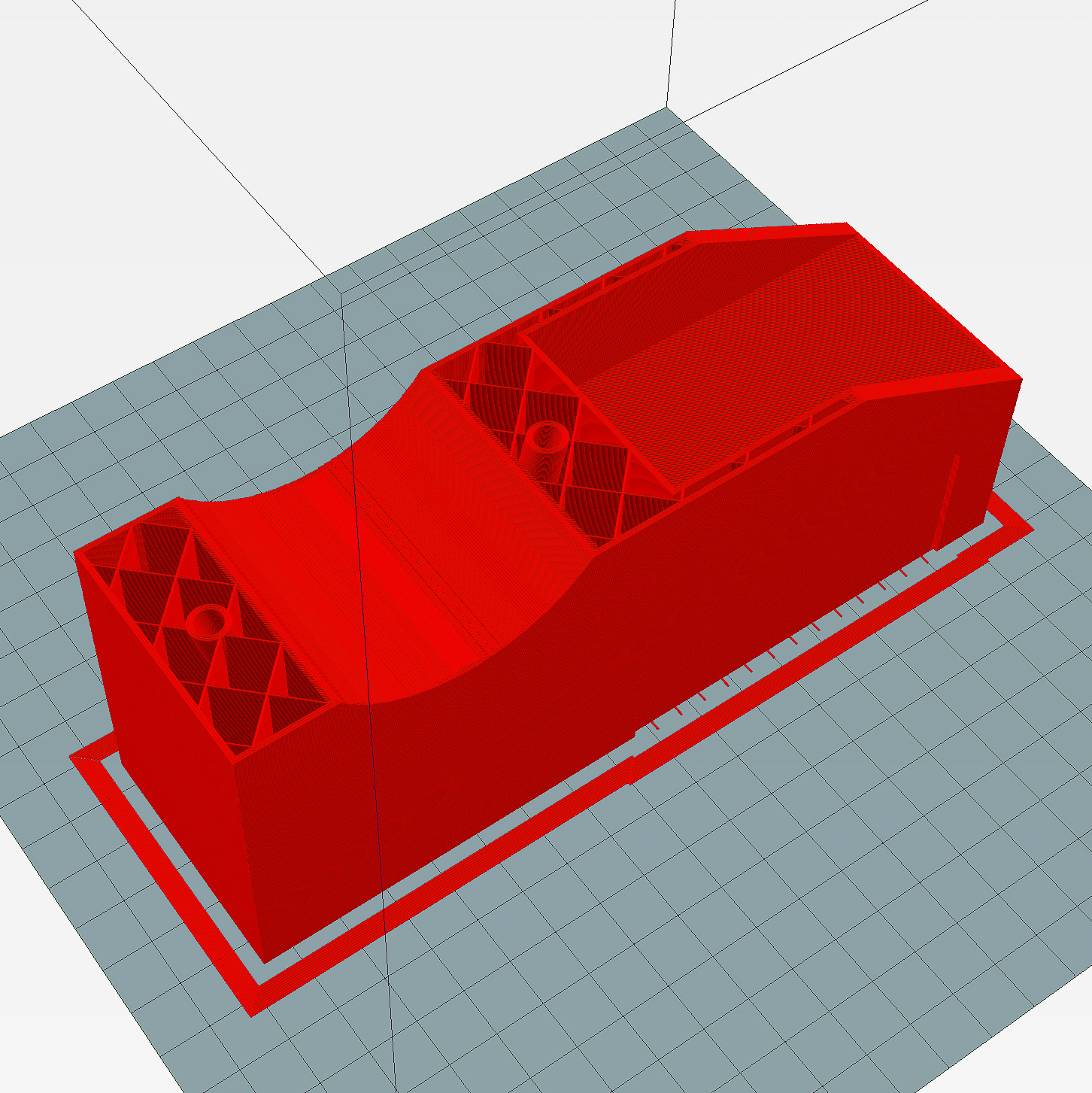

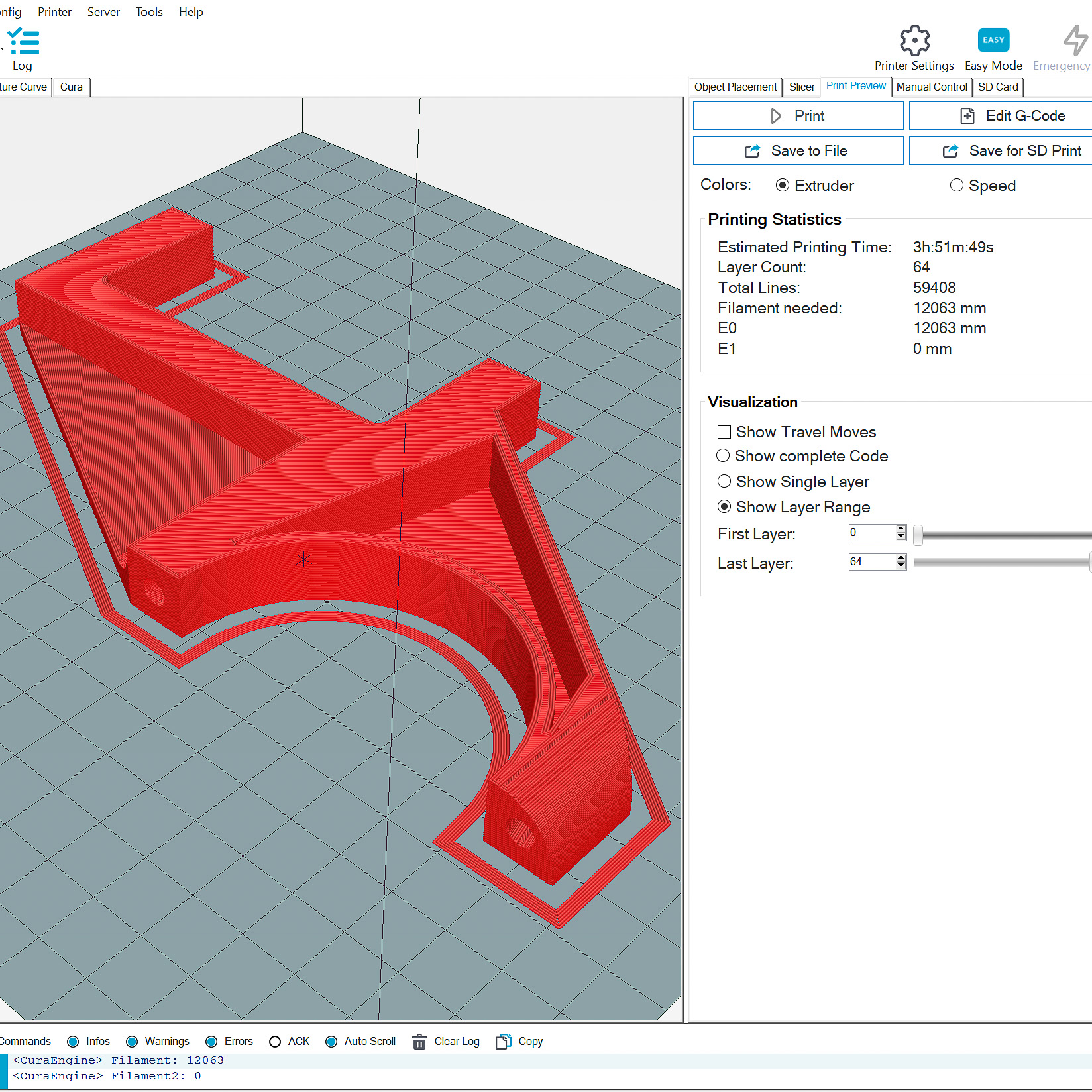

Designing the Locating Jig Slicing the CAD Model for 3D printing.

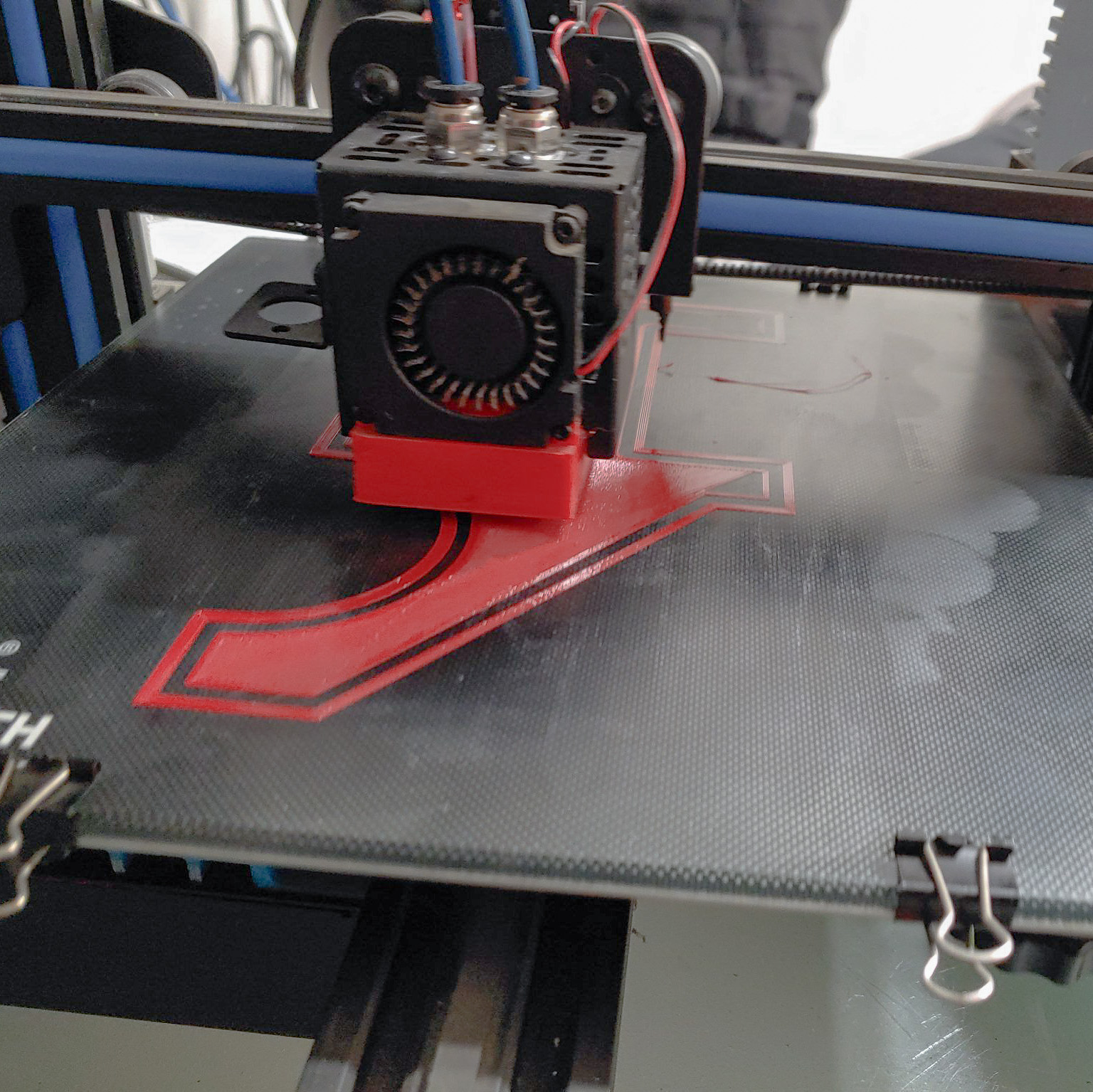

Slicing the CAD Model for 3D printing. The start of a 14 hour long print.

The start of a 14 hour long print. And done. But we can do better.

And done. But we can do better.  So we redesign to make the part use less materiel.

So we redesign to make the part use less materiel.  4 Hours, much better.

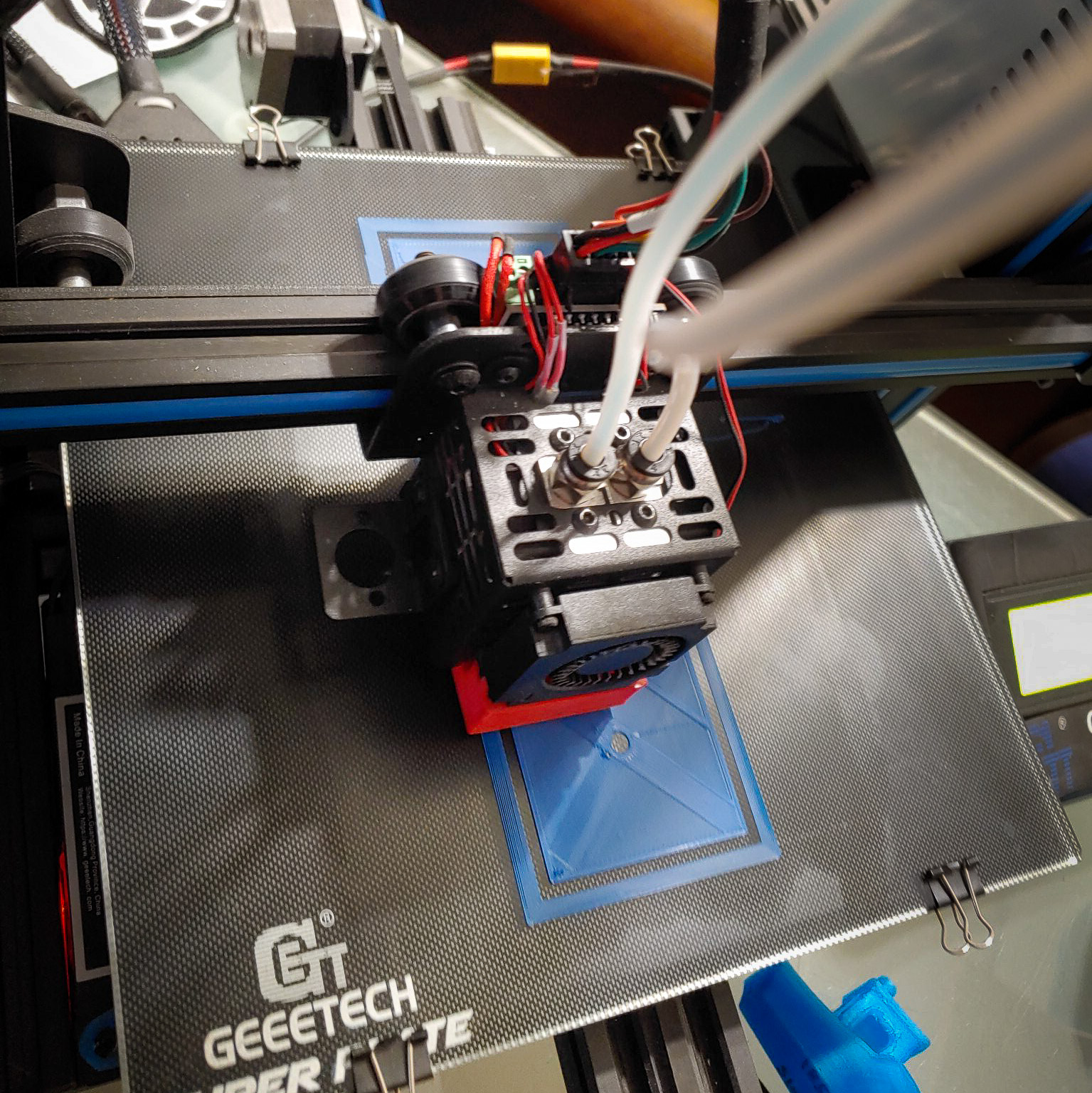

4 Hours, much better.  Kick off the print.

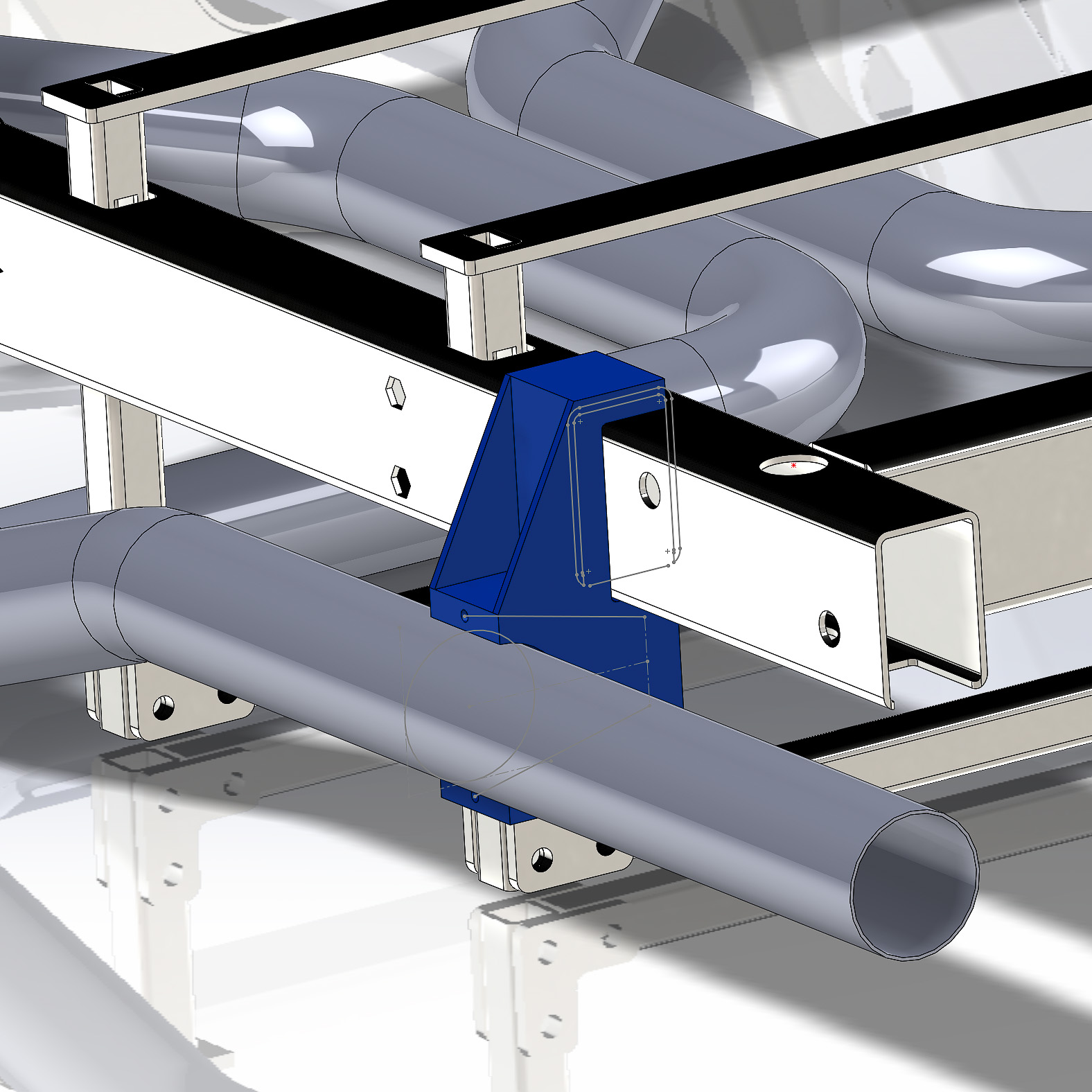

Kick off the print. And here we go. The tail pipe is located in relationship to the output and I can play connect the dots between the muffler and tail pipe.

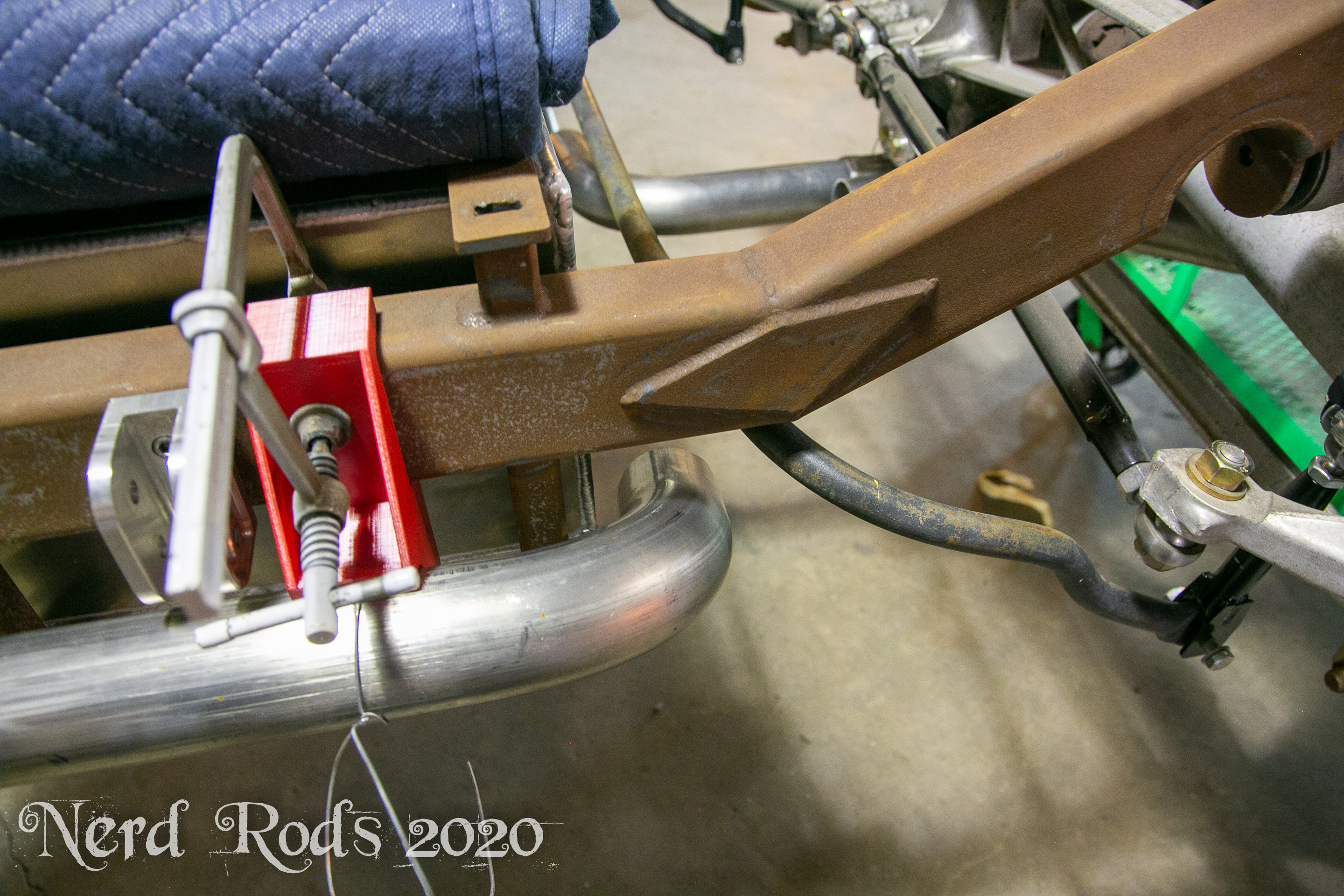

And here we go. The tail pipe is located in relationship to the output and I can play connect the dots between the muffler and tail pipe.

Under the sway-bar at full droop, and around the fuel tank.

Under the sway-bar at full droop, and around the fuel tank.  Like I said, connect the dots with tubing, But this is much easier than how we used to do it, and so much more accurate.

Like I said, connect the dots with tubing, But this is much easier than how we used to do it, and so much more accurate. Thanks for reading, I might do more of these if the bug strikes. Thanks for reading and I hope you've come up with some kind of idea for your own 3D printing project.

Later,

-Russell @ Nerd Rods